Aluminum Micro-Channel Tube

Group is a leading manufacturer for micro channel porous Aluminium Flat tubes with more than 9 years.

After years of accumulation, the group have formed a complete Aluminium alloy reseash and developments,production system can meet different technical requirements.

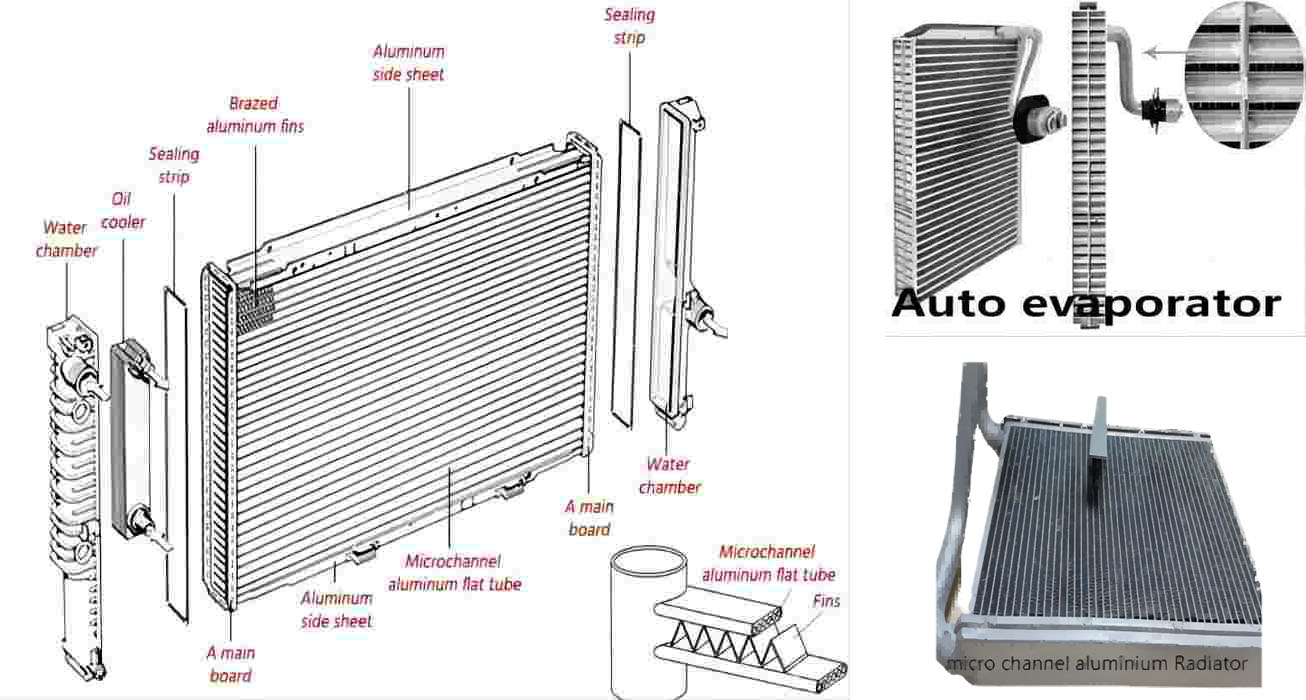

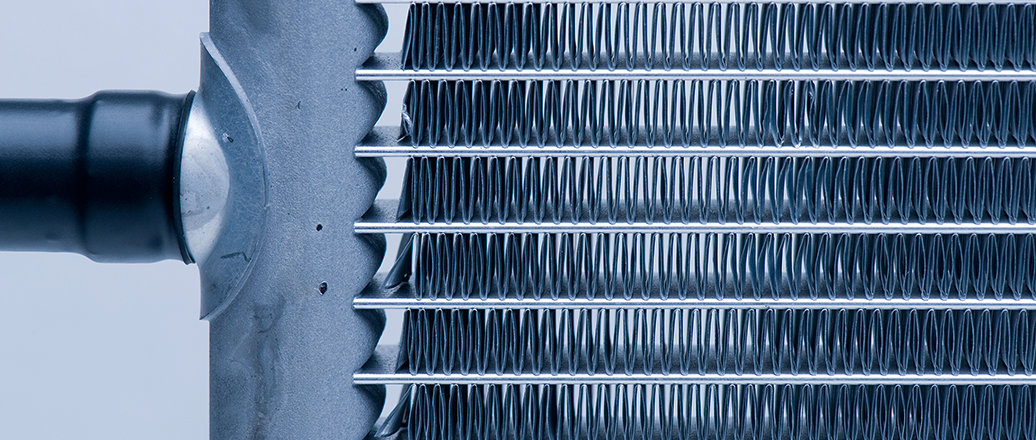

Currently, we produce and offer a full range of Aluminium porous channel flat tubes which are widely used in condensors and evaprators of heating elements in the field of home appliance, constrction industry as well as automobiles.

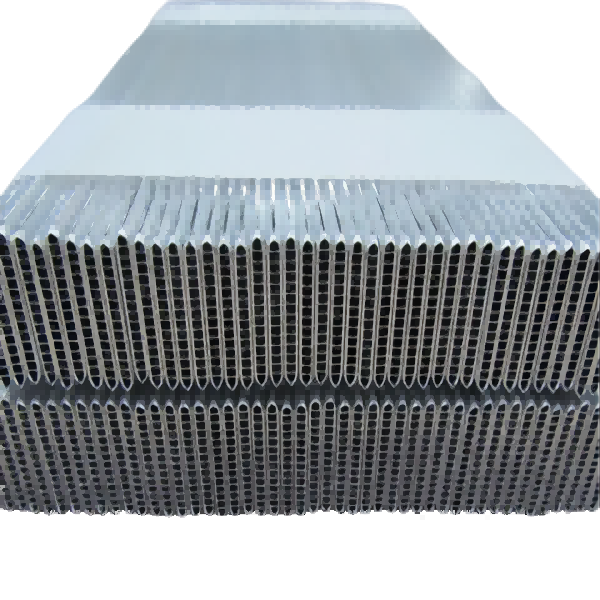

The Aluminium micro channel tubes PME tubes( also called parallel flow aluminium flat tubes) is a kind of thin-walled porous flat tubes, which is made of refined aluminium rod, hot extrusion, zinc spraying and anti-corrosion treatment.current annual capacities is about 1200mts.

Description

Aluminum micro-channel tube is a kind of high-precision extruded aluminum tube, also called multi-port extrusion tube (MPE tube) and an aluminum micro-channel tube. This flat, rectangular extruded tube is made of several channels that increase heat transfer through a higher surface-per-volume ratio.

Aluminum micro-channel tubes are available in various sizes and aluminum alloys, ensuring the best performance for the purpose required, and can be delivered with zinc or flux coating, ready for assembly and oven brazing.

Technical Parameters of Micro channel porous Aluminium Flat Tubes ( unti:mm)

Alloy |

AA1100.1050.3102.3003 |

|

Temper |

O, H12, H22, H14, H24, H18, H26, H112 |

|

Porous |

3 - 39 |

|

surface |

Mill finish or Zinc Spray layer (spray 5-15g/m2) |

|

width |

6 - 40mm ( +/-0.03mm) |

|

height |

1.0 - 4.0mm (+/-0.02mm) |

|

Wall thickness |

0.25 - 0.40mm ( +/-0.05mm) |

|

Rib thickness |

0.20 - 0.35mm ( +/-0.05mm) |

|

Side end wall thickness |

0.35 - 0.55mm ( +/-0.05mm) |

|

End necking width |

For positioning |

+/-0.03mm |

Non positioning |

+/-0.05mm |

|

End necking length |

For positioning |

3.0-7.0mm |

Non positioning |

1.0 - 3.0mm |

|

Specification of Micro channel porous Aluminium Flat Tubes ( unti:mm)

Specification |

length(mm) |

thickness(mm) |

number of holes |

Unit Weight (kg/m) |

8.5x2-3 |

8.5 |

2 |

3 |

0.0173 |

12x1.4- 12 |

12 |

1.4 |

12 |

0.0268 |

20x2-10 |

20 |

2 |

10 |

0.0523 |

16x1.3- 16 |

16 |

1.3 |

16 |

0.0364 |

22x1-24 |

22 |

1 |

24 |

0.0363 |

25.4x2- 28 |

25.4 |

2 |

28 |

0.0707 |

36x2-26 |

36 |

2 |

26 |

0.1047 |

25.4x1.3-26 |

25.4 |

1.3 |

26 |

0.0573 |

36x2-29 |

36 |

2 |

29 |

0.1418 |

60x2.5-28 |

60 |

2.5 |

60 |

0.1427 |

16x1.3- 19 |

16 |

1.3 |

19 |

0.0368 |

224x1.5- 11 |

22.4 |

1.5 |

11 |

0.0344 |

17x1.7- 14 |

17 |

1.7 |

14 |

0.0486 |

12x 1.2-12 |

12 |

1.2 |

12 |

0.0291 |

Mechinical Properties of Micro cahnnel porous Aluminium Flat Tubes At room temperature

Alloy |

Temper |

Tensile strength(Mpa) |

Yield strength Rp0.2 (Mpa) |

Elogation at 50mm (%) |

1050 |

|

≥60 |

≥20 |

≥23 |

1100 |

H112 |

≥75 |

≥20 |

≥20 |

3102 |

|

≥75 |

≥30 |

≥22 |

3003 |

|

≥95 |

≥35 |

≥20 |

Advantages of Aluminum Multi-channel Tube

Small cross-section

Big flatness ratio

Thin wall thickness

Strict qualifications

Customers’ aluminum parallel-flow type condenser tube design is available

Galvanized/zinced aluminum air conditioner evaporator tubes are available

Mainly used in heat exchangers for light vehicle air conditioning systems

Suitable for condensers and evaporators

For the special demands of the clients, qualified samples could be offered within one month according to the requirement.

Application For Micro channel porous Aluminium Flat Tubes At room temperature

Home appliance refrigeration, freezer, vehicle refregeration, base station cooling, industries refrigeration, specially applied in new energy power battery cooling systems,cooling modules for household appliance,As well as automotive air conditioners, civil air conditioners.