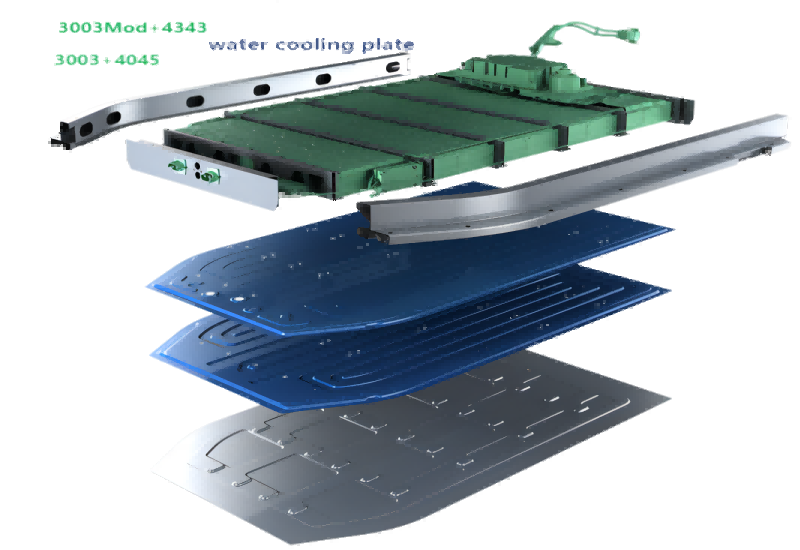

Aluminium Cooling plate and Battery shell

Aluminium Base plate for EV battery cooling plate

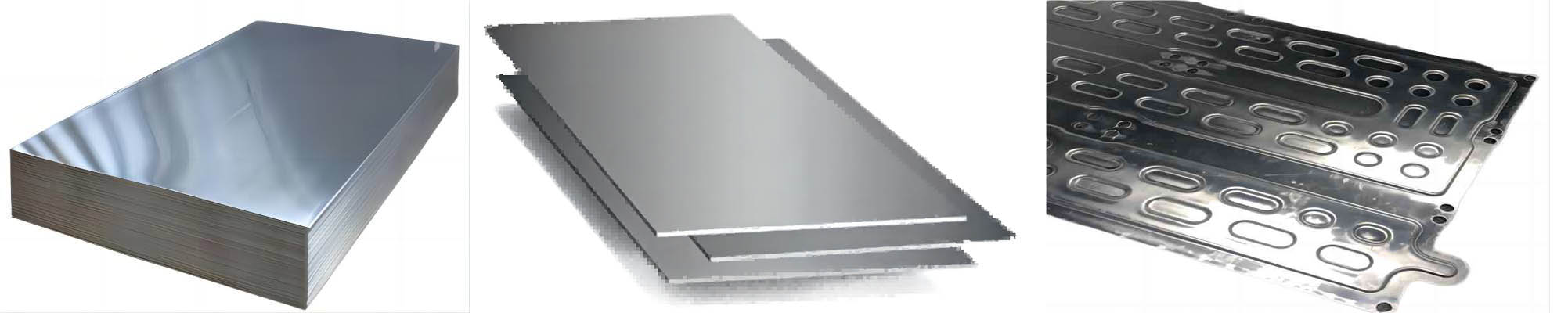

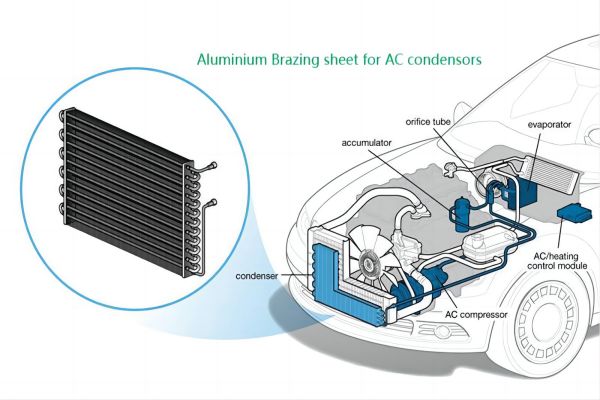

Aluminum plate for electric vehicle battery cooling panel is an aluminum alloy plate specially used for electric vehicle battery cooling system. Its main function is to effectively dissipate the heat generated in the battery through heat conduction and heat dissipation to ensure the normal operating temperature of the battery, thereby extending the service life of the battery and improving battery performance.

Commonly used aluminum plate alloy grades for electric vehicle battery cooling plates include 3003. Among them, 3003 aluminum plate alloy is a popular choice for battery cooling plates due to its excellent corrosion resistance and high thermal conductivity. Its corrosion resistance helps protect the cooling plate from degradation over time, and its thermal conductivity facilitates efficient heat transfer, contributing to effective battery cooling. 5052 aluminum plate is another commonly used material for battery cooling plates due to its high strength and good formability.

This enables the production of complex shapes and designs, which is important for optimizing the cooling performance of electric vehicle batteries. 6061 aluminum plate is a versatile material commonly used in a variety of applications, including battery cooling plates. It has excellent strength and corrosion resistance as well as good thermal conductivity, making it a reliable choice for electric vehicle battery cooling plates.

Alloy, Temper and Size of Aluminum Cladding plate for EV battery cooling plate

Item |

Product |

Alloy |

strength |

Temper |

Cladding Rate(%) |

thickness(mm) |

width(mm) |

Length |

1 |

Cooling bottomplate |

3003 |

Normal |

0 |

/ |

0.5~4.0 |

200~1240 |

600~2000 |

3003MOD1 |

middle |

0 |

||||||

7072/3003MOD1 |

3~13 |

|||||||

3003MOD2 |

high |

0、H24 |

/ |

|||||

3003MOD3 |

||||||||

7072/3003MOD2 |

3~13 |

|||||||

7072/3003MOD3 |

||||||||

2 |

Cooling Runner plate |

4343/3003 |

Normal |

0 |

3~13 |

0.5~4.0 |

200~1240 |

600~2000 |

4045/3003 |

||||||||

4343/3003MOD1 |

Middle |

|||||||

4045/3003MOD1 |

||||||||

4343/3003MOD1/7072 |

||||||||

4045/3003MOD1/7072 |

||||||||

4343/3003MOD2 |

High |

|||||||

4045/3003MOD2 |

||||||||

4343/3003MOD3 |

||||||||

4045/3003MOD3 |

||||||||

4343/3003MOD2/7072 |

||||||||

4045/3003MOD2/7072 |

||||||||

4343/3003MOD3/7072 |

||||||||

4045/3003MOD3/7072 |

NOte1:7072 belong to sacrificial anti-corrosion layer, 4XXX belong to brazing layer ,3XXX is core material

Note2:Alloy grade comfirm to stipulation of GB/T 27675

Note3:both sides can decide and discussion if customer need special grade, temper, cladding rate etc and stipulated in the ordert

Chemical composition of Aluminium core and Aluminium Cladding plate for EV battery Cooling plate

Alloy |

Chemical compostion % |

|||||||||

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Ti |

others |

Al |

||

single |

Others total |

|||||||||

3003 |

≤0.6 |

≤0.7 |

0.02-0.20 |

1.0-1.5 |

≤0.05 |

≤0.1 |

≤0.05 |

≤0.05 |

≤0.15 |

rest |

3003MOD1 |

≤0.6 |

≤0.7 |

0.4-0.6 |

1.0-1.5 |

≤0.05 |

≤0.1 |

≤0.25 |

≤0.05 |

≤0.15 |

rest |

3003MOD2 |

0.5-0.9 |

≤0.7 |

0.4-0.6 |

1.3-1.8 |

≤0.05 |

≤0.1 |

≤0.25 |

≤0.05 |

≤0.15 |

rest |

3003MOD3 |

0.5-0.9 |

≤0.7 |

0.65-1.0 |

1.3-1.8 |

≤0.05 |

≤0.1 |

≤0.25 |

≤0.05 |

≤0.15 |

rest |

4343 |

6.8-8.2 |

≤0.8 |

≤0.25 |

≤0.1 |

≤0.05 |

≤0.2 |

≤0.05 |

≤0.05 |

≤0.15 |

rest |

4045 |

9.0-11.0 |

≤0.8 |

≤0.30 |

≤0.05 |

≤0.05 |

≤0.10 |

≤0.20 |

≤0.05 |

≤0.15 |

rest |

7072 |

Si+Fe≤0.7 |

≤0.10 |

≤0.10 |

≤0.10 |

0.8-1.3 |

≤0.05 |

≤0.05 |

≤0.15 |

rest |

|

Tolerance of Cladding ratio

Cladding ratio(%) |

Cladding ratio Tolerance(%) |

3.0~6.0 |

±1 |

>6.0~8.0 |

±1.5 |

>8.0~13.0 |

±2.0 |

Thickness tolerance for EV battery cooling Plates

Thickness/mm |

Thickness tolerance /mm |

0.50~0.59 |

±0.015 |

0.60~0.79 |

±0.025 |

0.80~1.50 |

±0.030 |

1.51~2.00 |

±0.050 |

Width tolerance for EV battery cooling Plates

Width /mm |

Width Tolerance/mm |

200-600 |

±1.0 |

>600-1300 |

±1.5 |

>1300-2000 |

±2.0 |

Tolerance for EV battery cooling Plates

Length /mm |

Length tolerance /mm |

600~1000 |

±2.0 |

>1000~2000 |

±2.5 |

>2000~3000 |

±3.0 |

Diagonal tolerance of EV Battery cooling plates

Length mm |

Diagonal tolerance mm |

|

600~1000 |

≤ 3 |

|

>1000~2000 |

When width ≤1000mm ,≤3 , when width >1000-1500mm,≤4 |

|

>2000~3000 |

Width ≤1500mm ,≤4 width >1500-2000mm,≤6 |

|

Flatness of EV Battery cooling plates

Thickness mm |

Flatness mm |

0.5~1.0 |

≤3 |

>1.0~2.0 |

≤5 |

Curve of EV Battery cooling plates

Width mm |

Side curve allowance mm |

200~600 |

Length ≤1000mm ,≤1 Length >1000-2000mm ,≤1.5 Length>2000-3000mm 时,≤2 |

>600~1000 |

Length ≤1000mm 时,≤1 Length >1000-2000mm ,≤1.5 Length >2000-3000mm ,≤2 |

>1000~2000 |

Length ≤1000mm 时,≤1.5 Length >1000-2000mm ,≤2 Length >2000-3000mm ,≤2.5 |

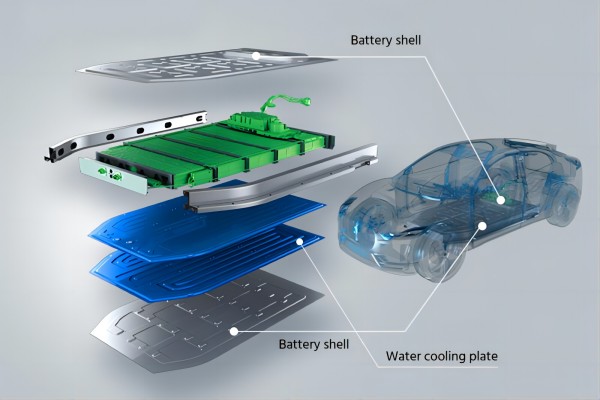

AA3003 /3003 Mod Aluminum Sheet/Coil Used As Power Battery Shell

Introduction

3003 Aluminum sheet alloys are preferred to be used in power battery casing materials. To find out the best material for the structure of a power battery, first you must know what a power battery is.

The global electric vehicle industry has basically agreed that the battery that provides the driving force to electric vehicles is called a power battery including traditional lead-acid batteries, nickel metal hydride batteries and emerging lithium-ion energy batteries. Now the world is currently defending lightweight cars, aluminum is the best choice.

3003 aluminum has good formability, mainly used in deeply drawn materials, 3003 aluminum alloy products are used for stamping parts, mannequins, shells. 3003 Aluminum sheet as the power battery casing material is one of the superior products. It has mature technology, excellent quality and global distribution.

Specification

Alloy:AA3003

Temper: H14

Thickness: 0.8mm -3.0mm

Standard width” 200-1200mm

AA3003 characteristics for power battery shell

Lightweight: compared with other metal materials, aluminum alloy is relatively light and has a good strength-to-weight ratio, which can reduce the weight of the entire battery system and improve the energy efficiency and cruising range of electric vehicles.

High strength: aluminum alloy has high strength, which can provide good structural support and impact resistance, and protect the battery module from external shock and vibration.

Good thermal conductivity: aluminum alloy has excellent thermal conductivity, which can effectively conduct the heat generated inside the battery, improve the heat dissipation efficiency of the battery, and keep the temperature of the battery stable.

Good corrosion resistance: aluminum alloy has good corrosion resistance, and can maintain a stable surface state under harsh environmental conditions, prolonging the service life of the battery case.

Strong plasticity: aluminum alloy has good plasticity and processability, and is easy to form and process into complex shapes, meeting the needs of battery case manufacturing with different design requirements.