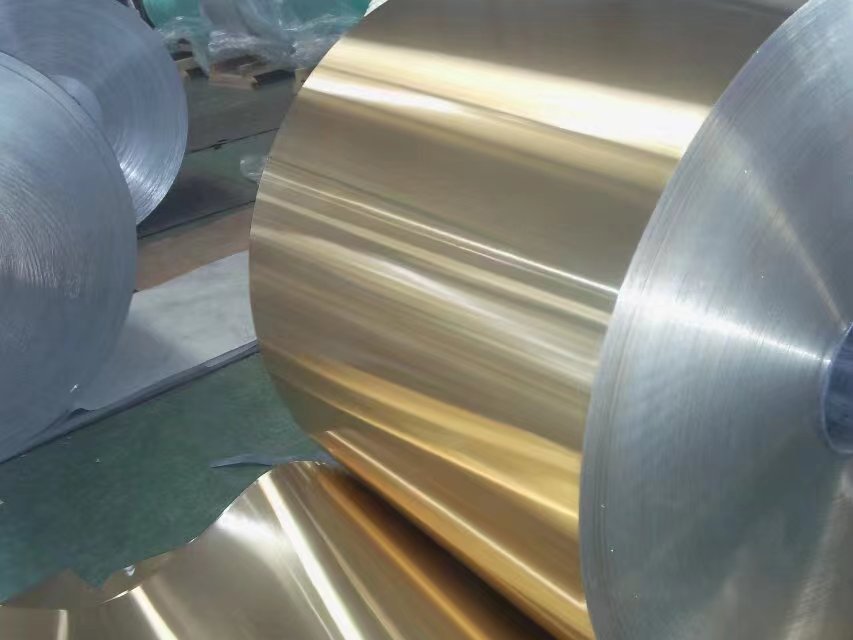

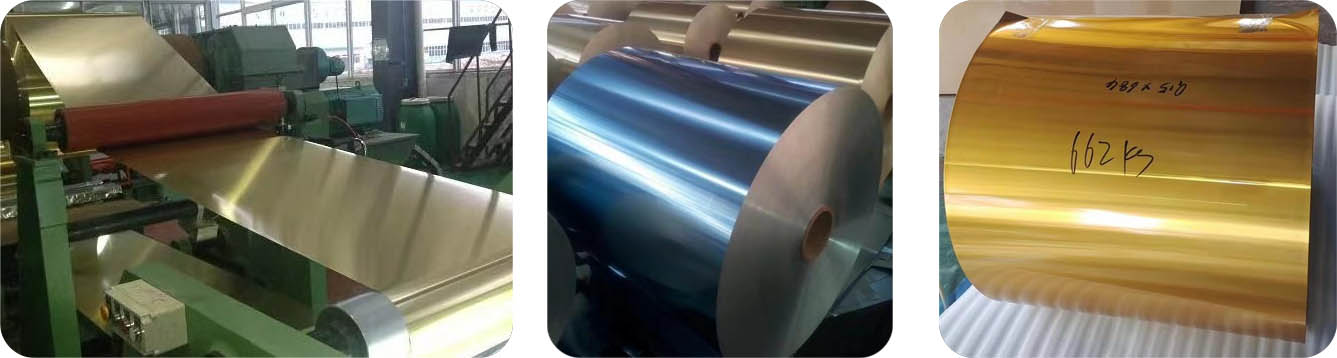

Aluminium Hydrophlic/Hydrophobic Finstock

Description

We are professional manufacturer of aluminium bare foil and hydrophlic foil for fin stock used in Air conditioner like heat exchanger, condenser, evaporator, radiator etc. With 4 aluminium foil coating lines and 15 years of production experience, we are continouls exporting our products to middle east, korea, thailand, belgium etc with superior quality and excellent service.

Annual capacity of 42000mts aluminium coating foils with four colors are avaliable the general use of air-conditioning heat exchanger hydrophilic coating are organic hydrophilic coating, the common organic hydrophilic coating color is blue and gold.

Specification

Alloy:AA1100/8011/3102

Temper:O,H18/22/24/26/

Thickness: 0.08mm - 0.20mm

Width: 100mm - 1350mm

Roll ID:75/150/505

Tolerance

Thickness and tolerance |

Width and tolerance (mm) |

Core ID (mm) |

Max OD for Finish products (mm) |

Core material |

0.08~0.02 (+/-0.005) |

100~1100(+/-0.5) |

∮75, ∮150, |

∮</=1400 |

Paper,aluminium,steel |

Hydrophlic color and type

| Hydrophlic type/Color | Alloy |

Temper |

size |

|

Organatic |

Golden |

AA1100 |

H22/24/26/0 |

Thickness: 0.08 - 0.2mm |

Non-Organatic |

Milky white/silk |

|||

Production Chart

Casting → Cold Rolling → Foil Rolling → Anneaning → solidification → prime coating → drying → cleaning → Degressing → Face coating → Sodification → winding inspection → Slitting → packaging → Inspection.

We have the technology of 3th layer coating (chemical conversion coating + 2 coating), with which we can meet the demands for multifunctional fin stock of our customers.

Inspection standard for hydrophilic aluminum foil( AA3102 as samples)

|

item |

standard |

Inspection methods |

||

3102-H26 |

frequency |

Testing tools |

condition |

||

1 |

Tensile (Mpa) |

125-145 |

1time /Coil |

Tension tester |

sample |

Elogation (%) |

≥14% |

||||

Enriches(mm) |

≥4.0 |

Enriches gauge |

sample |

||

2 |

Iinitail hydrophlicity |

≤5° |

1time /Coil |

5ul Syringe |

sample |

3 |

Continous hydrophlicity |

≤26° |

1 time/lot |

5ul Syringe |

sample |

4 |

Adhesion force |

NO DELAMINATION |

1time/Coil |

Tape |

sample |

5 |

Salt-Spray Corrosion Test |

500h\RN≥9.5 UP |

1 time/ Quarter |

Salt-Spray |

sample |

6 |

Alkaline resistance test |

25 min For 10% NaOH solution The surface has no white spot, blister, fall off and other phenomena |

1 time/COIL |

Visual |

sample |

7 |

Thickness Tolerance(mm) |

± 0.005 |

1 time /Coil |

Micrometer |

sample |

8 |

Width Tolerance (mm) |

± 0.5 |

1time /Coil |

Tape measure |

sample |

9 |

Spool/core (I.D) (mm) |

∮200± 2.0 |

1time /Coil |

Tape measure |

sample |

10 |

Coil outer Dia.(mm) |

∮700~1000 |

1 time/Coil |

Tape measure |

sample |

11 |

surface |

No color difference |

1 time/coil |

Visual |

sample |

NO scratch |

|||||

Mechanical Properies

Alloy |

Temper |

Mechanical performance under room temperature |

||

Tensile(∮b, Mpa) |

Elongation(e%) |

Erichson(IE,mm) |

||

1100, 8011.3102 |

O |

80-110 |

>20 |

>6.0 |

H22 |

100-135 |

>16 |

>5.5 |

|

H24 |

115-145 |

>12 |

>5.0 |

|

H26 |

125-160 |

>8 |

>4.0 |

|

H18 |

>160 |

>1 |

-- |

|

Re:if customers have special requirements,pls indicate them in purchase order |

||||