Aluminum high precision plates

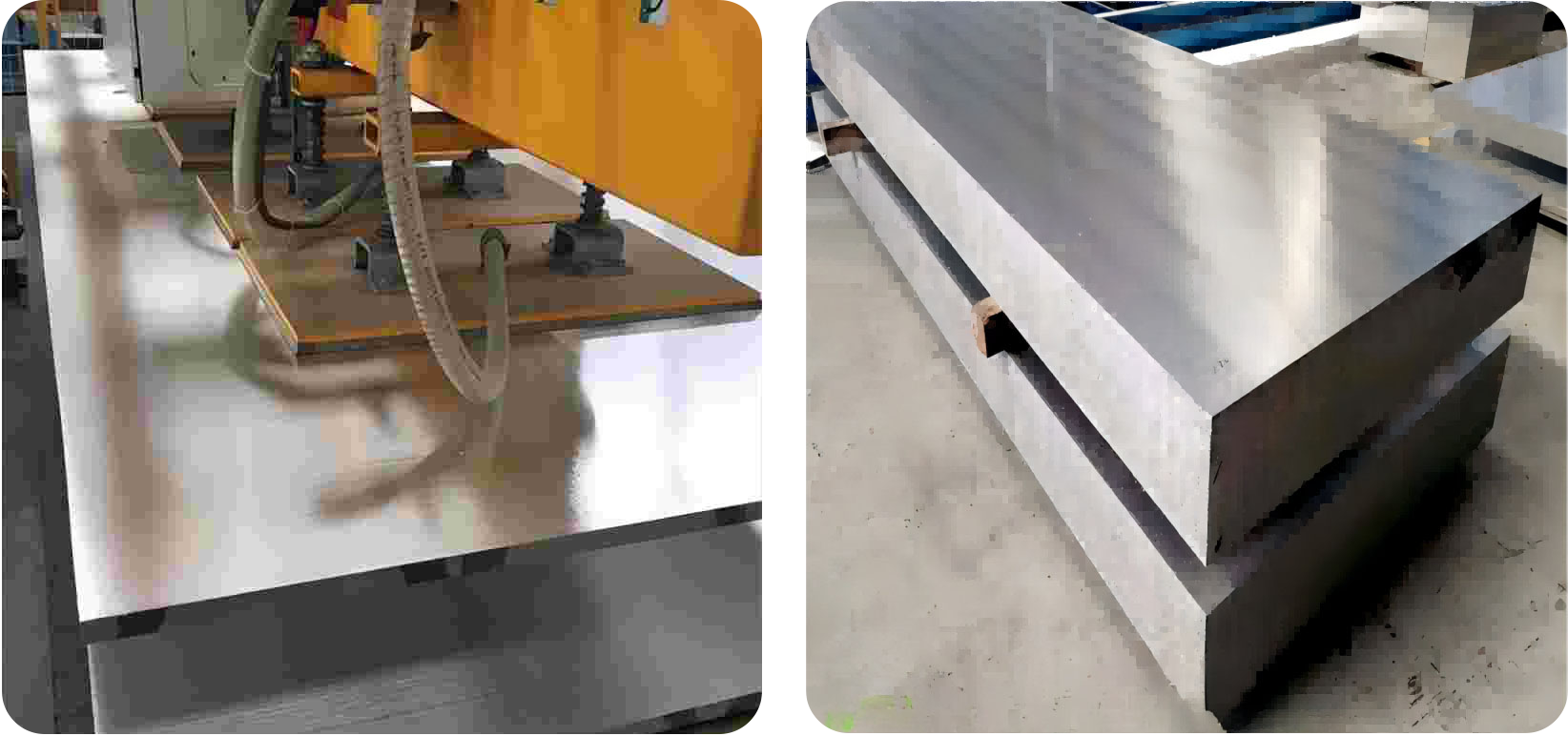

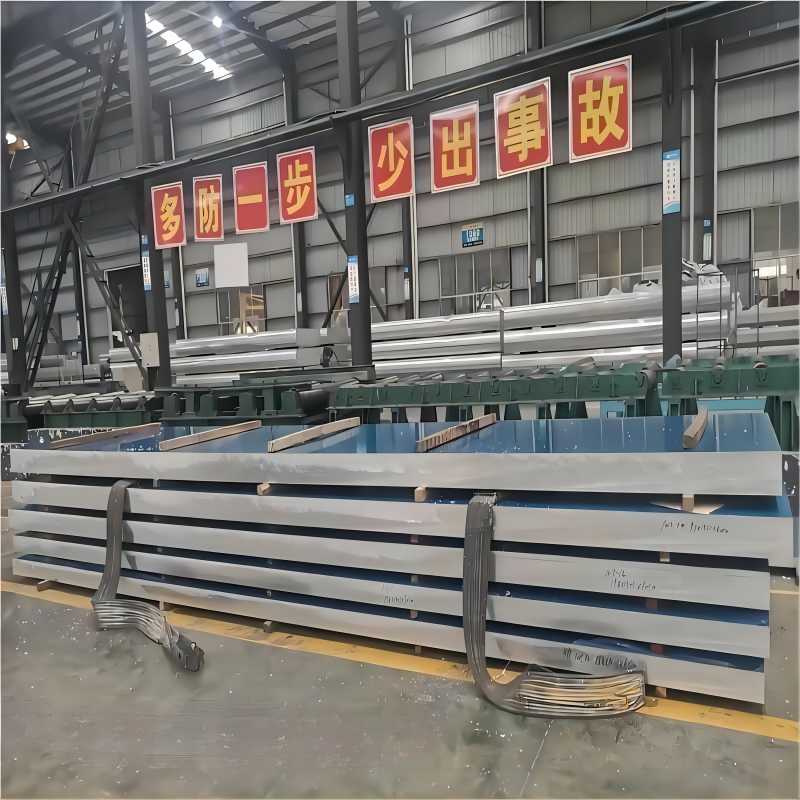

This product has outstanding machinability, excellent high-speed cutting rates, and exceptional feed rates, all of which contribute to reducing machining time and improving efficiency.we offers improved performance characteristics when compared to standard aluminum tooling plate, including stringent flatness tolerances that are unsurpassed in the industry.

Comparasion between High Precision Aluminium Plates and common Aluminium plates

Application |

Surface |

Thickness |

Tolerance |

Flatness (mm/㎡) |

Features |

Commercial |

Brushed |

6-55 |

+/-0.075 |

≤0.3 |

Surface processing no necessary,no deformation when sawing and machinning |

Mill finish |

60-250 |

+/-0.1 |

≤0.3 |

minor surface processing, no deformation when sawing and machining |

|

High precision |

Brushed |

6-20 |

+/-0.05 |

≤0.3 |

Surface processing no necessary,no deformation when sawing and machinning |

22-55 |

+/-0.06 |

≤0.3 |

|||

Mill finish |

60-250 |

+/-0.07 |

≤0.5 |

minor surface processing, no deformation when sawing and machining |

|

Super flatness |

Brushed |

6-20 |

+/-0.03 |

≤0.3 |

No necessary of processing for brushed surface, minor processing for mill finish furface, no deformation ehen sawing and machining |

Main features of high-precision aluminum sheet

Excellent anodizing and hardening reaction

Higher strength and elongation

Excellent solderability

Improve corrosion resistance

High strength to weight ratio

Dimensional stability

Provide design engineers with precision products for demanding and critical applications

Both sides provide PVC material

100% test the flatness and thickness accuracy of each sheet