Aluminium Brazing Material

Introduction:

We are leading manufacturer for Brazing Aluminium Alloy composite material, after years of accumulation,the group have formed a complete Aluminium alloy reseash and developments,production system,can meet different technical requirements.

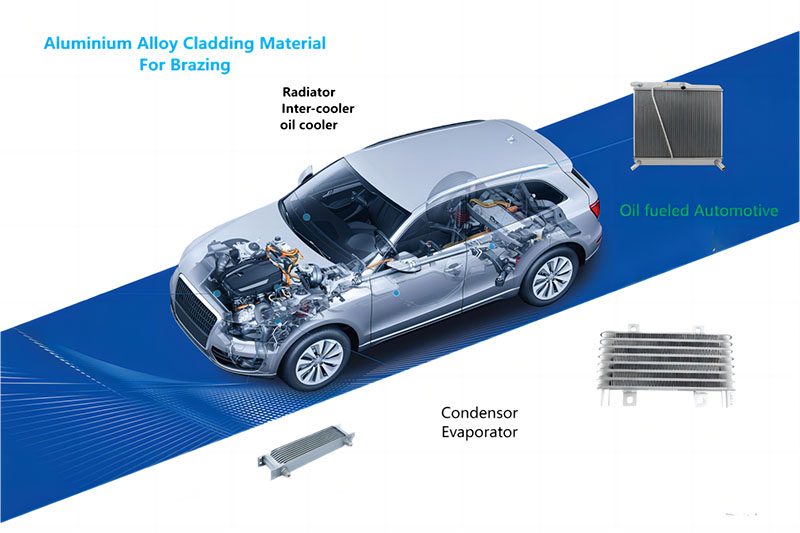

Currently, we produce and offer a full range of rolled aluminuim products for heat exchanger manufacturers,including different series of aluminium, various specification and temper,which are widely used in automotive, construction machine,micro-channel condensors,evaporators,power plant,air-conditioner for residents and business, and battery case/foil for new energy vehicle.monthly capacility of about 4000mts

The classification of brazing aluminum sheet foil coil strip

Brazing aluminum sheet foil coil strip can be divided into aluminum alloy clad materials such as single -sided cladding, double -sided cladding, etc.

The non-clad materials of aluminum alloy are mainly supporting the use of clad aluminum brazing material for manufacturing various welding heat exchangers.

The typical combination of welding brazing alloy is 4045/3003/4045, 4045/3003/7072, 4045/3A11/4045 , 4045/7A11/7072, 4343/3003/4343 etc.

The application of brazing aluminum sheet foil coil strip

The Brazing aluminum sheet foil coil strip, also known as Al-SI brazing material, is the most widely used aluminum-based brazing material. The typical AL-SI dual series of brazing material is 4343 , 4045 , 4047 , etc.

The Brazing aluminum sheet foil coil strip are widely used in automotive heat exchange systems, such as engine radiators, engine oil radiator, medium refrigerator, air -conditioning condenser and evaporator etc.

Specification of Aluminium and Aluminium Alloy Brazing material

item |

commodity |

Alloy |

Temper |

Main specification(mm) |

Main Application |

||

|

thickness |

width |

length |

||||

1 |

Cladding strip/foil |

4343/ZX309/4343 |

H14/H16 |

0.07-0.3 |

12-600mm |

Coil/strip |

Automobile heat exchanger fin |

2 |

Cladding sheets |

4343/3003/4343 |

O |

0.4-0.9 |

40-1240mm |

Coil |

Stacked Evaporators |

3 |

Cladding Plate |

4343/3003/4343 |

H14/O |

1.0-4.0 |

16-1240mm |

Coil |

Main board, side board of heat exchanger |

4 |

Cladding plate |

4343/ZX307/7072 |

O |

1.0-2.5 |

1000-1240mm |

750-2500mm |

Water cooling plate for power storage |

5 |

Non-cladding strip |

3003+zn |

H14/H16 |

0.07-0.3 |

12-600mm |

Coil/strip |

Automobile heat exchanger fin |

6 |

Non-cladding plate |

3003 |

H14/O |

1.0-4.0 |

16-1240mm |

Coil |

Main board, side board of heat exchanger |

7 |

6061 automobile plate |

6061 |

O |

1.5-2.5 |

800-1300mm |

800-2500mm |

Automobile decoration |

Aluminium and Aluminium Alloy Cladding material for heater exchanger

Alloy: 4343/3003/4343, 4343/3003/7072, 4045/3003/4045, 4104/3003/4104, 4004/3003/4004

Core Material: 3003,3003mod,3003+zn

Cladding Material: 4343,4045,7072

Core Material

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Zr |

Ti |

代号 |

3003 |

0.6 |

0.7 |

0.05-0.20 |

1.0-1.5 |

- |

0.1 |

0.05 |

0.03 |

1 |

3003+1%Zn |

0.6 |

0.7 |

0.05-0.20 |

1.0-1.5 |

- |

0.5-1.50 |

0.05 |

0.05 |

2 |

3003+1.5%Zn |

0.6 |

0.7 |

0.05-0.20 |

1.0-1.5 |

- |

1.0-2.0 |

0.05 |

0.05 |

3 |

3003+1.5%Zn+Zr |

0.5-1.0 |

0.7 |

0.05-0.20 |

1.0-1.6 |

- |

1.0-2.0 |

0.05-0.2 |

- |

4 |

3003+0.5%Cu |

0.6 |

0.7 |

0.30-0.70 |

1.0-1.5 |

- |

0.10 |

0.05 |

0.1 |

5 |

3005 |

0.6 |

0.7 |

0.20-0.40 |

1.0-1.5 |

0.20-0.60 |

0.25 |

- |

0.01 |

6 |

Cladding Material

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Zr |

Ti |

代号 |

4343 |

6.8-8.2 |

0.8 |

0.25 |

0.1 |

- |

0.2 |

- |

0.05 |

1 |

4343+1%Zn |

6.8-8.2 |

0.8 |

0.25 |

0.1 |

- |

0.5-1.5 |

- |

0.05 |

2 |

4045 |

9.0-11.0 |

0.8 |

0.3 |

0.05 |

- |

0.2 |

- |

0.2 |

3 |

4045+1%Zn |

9.0-11.0 |

0.8 |

0.3 |

0.05 |

- |

0.5-1.5 |

- |

0.2 |

4 |

4004 |

9.0-10.5 |

0.8 |

0.25 |

0.1 |

1.0-2.0 |

0.2 |

- |

0.2 |

5 |

7072 |

0.7 |

0.1 |

0.1 |

0.1 |

0.8-1.3 |

- |

- |

6 |

|

5005 |

0.3 |

0.7 |

0.2 |

0.2 |

0.5-1.1 |

0.5-1.0 |

- |

0.03 |

7 |

Produce Capability

|

(mm)Width |

(mm)Thickness |

(mm)Length |

(mm)Inside Diameters |

Sheet |

500-1070 |

0.5-4.0 |

500-2500 |

- |

Strip |

13-1200 |

0.2-3.0 |

- |

150、200、300、400、500 |

Foil |

13-1200 |

0.06-0.2 |

- |

150、200、300、400、500 |

Composite Ratio

Composite ratio |

4-18% each side |

Cladding Tolerance

Percent Clad(per side) |

4-8% |

> 8-18% |

Cladding tolerance |

±1.5% |

±2.0% |